Supercritical CO₂ pipelines operate in a thermodynamic regime where conventional equations of state and property tables quietly fail. This article explains why accurate leak detection and pipeline design in this region is fundamentally a thermodynamics problem and how Vanmok’s approach addresses it.

Design and Leak Detection in Supercritical CO₂ Pipelines Is a Thermodynamics Problem

Pipeline design and reliable leak detection in supercritical CO₂ pipelines cannot be built on simplified thermodynamic assumptions or equations of state (EoS) chosen only for steady-state convenience. Instead, it requires thermodynamic modeling that:

- Remains accurate near critical and phase-envelope regions

- Is computationally efficient enough for real-time RTTM/CPM use

- Accounts for composition sensitivity and dynamic phase behavior during transients

This is where most existing approaches begin to break down.

The Practical Dilemma Inside Every CO₂ Simulator

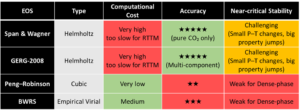

When modeling dense-phase CO₂ pipelines, engineers face an unavoidable trade-off between thermodynamic fidelity and computational practicality:

- Helmholtz models: thermodynamically accurate but computationally heavy for RTTM

- Cubic EoS: computationally efficient but unreliable near critical and phase-envelope regions

- Multi-parameter models: impractical for real-time use

- Composition dynamics: poorly handled in most CPM systems

Why Supercritical CO₂ Cannot Be Treated Like a Normal Liquid

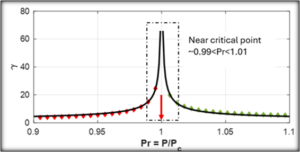

Near the critical point, CO₂ behaves in a way that is fundamentally different from conventional pipeline fluids:

- Property variation near the critical region is extremely nonlinear

- Small modeling shortcuts in density, compressibility, or heat capacity create large transient prediction errors

- Standard hydraulic assumptions used in liquid pipelines do not hold

- Correct transient prediction requires tight coupling between dense-phase thermodynamics and the transient PDE solver

In short: simplified property tables or coarse EoS approximations cannot produce correct transient behavior for CO₂ pipelines operating near critical conditions.

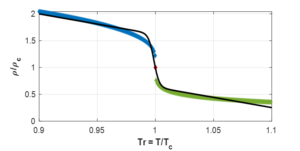

The Real Root Cause: A Critical-Point Discontinuity

There is a discontinuity in tabulated and EoS-based thermodynamic properties as the fluid crosses the critical point.

This discontinuity is what destabilizes RTTM/CPM solvers and leads to large modeling errors during transients.

Vanmok’s Approach: Regularizing Thermodynamics for Real-Time Use

To overcome this, Vanmok adopted the regularization approach described in PSIG-2324. ⬅ Click here

Instead of modifying existing EoS such as PR, Vanmok replaces property lookup and EoS evaluation near the critical region with analytically derived, continuous correlations expressed in reduced variables.

These auxiliary constitutive equations:

- Are continuous across and

- Are analytical, not tabulated

- Are free of singularities

- Are derived from reduced density and heat capacity behavior

Most importantly, these correlations are embedded directly into the transient PDE solver, producing a continuous thermodynamic field across gas, liquid, critical, and supercritical regimes.

Vanmok approach bridges the Gap Between Physics and Real-Time Simulation

This approach reconciles what the literature identifies as the central conflict:

- The need for high thermodynamic fidelity near the critical region

- The need for computational practicality in real-time leak detection and transient analysis

It enables purpose-built dense-phase CO₂ simulation that supports both accurate pipeline design studies and reliable leak detection under real operating conditions.

How Vanmok Can Help?

Vanmok Leak Detection Technologies helps operators and engineering teams address this risk early and systematically through Vanmok CO₂ Simulator.

Our simulator is purpose-built to model dense-phase CO₂ pipelines across all operating regimes, steady state, transients, shut-ins, restarts, and regime transitions, without breaking thermodynamics near the critical point. It enables teams to run high-fidelity what-if scenarios. ⬅ Click here

By applying physically consistent modeling upfront, companies can reduce design uncertainty during FEED, avoid fragile assumptions in operations, and deploy leak detection systems with confidence in real-world conditions.

If you are designing, operating, or regulating CO₂ pipelines and want to understand how near-critical physics truly impacts safety and detectability, contact Vanmok at 780-989-286 or info@vanmok.com to discuss how our CO₂ Simulator can support your FEED studies, operational readiness, and leak detection strategy.

Near-critical physics does not forgive shortcuts—but the right modeling framework can turn it into a competitive advantage.