Vanmok developed an Innovative Approach for Rupture/Leak Detection on Short Pipelines using only pressure transmitters.

Our technology provides a cost-effective solution for notification and identification of ruptures of 5% or greater within 15 minutes, relying solely on pressure transmitter data. This eliminates the need for SCADA and flow meters, making compliance with the new rule easier and more efficient.

*[DOCKET NO. PHMSA-2013-0255 Amdt. Nos. 192-130 195-105 ] [Document Number: 2022-07133 CFR: 49 CFR 192 49 CFR 195]

**PHMSA initially suggested 10 minutes time limit but after receiving the comments, decided not to include it in the final rule.

Reliable leak detection system that is autonomous and cost effective without requiring expensive SACAD/telemetry, flow meters and associated piping modifications.

Vanmok LD Cloud is a cost effective, real-time and autonomous solution for leak detection in saltwater pipeline networks. The field proven technology can detect the leaks from pinholes to large ruptures in less than few minutes by using proprietary algorithms for leak detection.

Customer: “How can we implement leak detection that is cost effective, SCADA independent, scalable on large number of short lines to meet PHMSA new final rule that requires >10% leaks detected within 15 minutes? ”

Vanmok LD Cloud is the answer!

Relies on pressure transmitter data only.

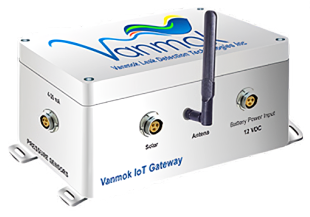

Dedicated Vanmok loT gateway scans data at 50 milli seconds and communicates to Cloud through cellular network (LTE-M or LTE-4G)

Built-in Vanmok A.I analyses all alarms and validates before alerting the operators.

Low power Vamok Gateways are supplied with integrated solar system to work offgrid.

Notifies and identifies leaks from 5% or greater within 15 minutes using only pressure transmitters.

Eliminates the need to modify existing piping to install flowmeters, saving expenses on both piping modifications and flowmeters.