In today’s competitive oil and gas industry, staying ahead means leveraging technology that not only meets current needs but also anticipates future challenges. That’s where our game-changing leak detection software comes into play.

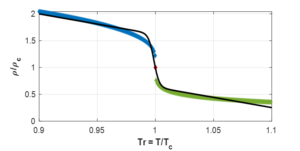

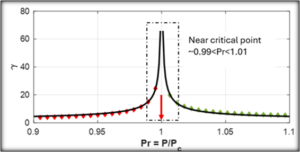

Engineered to provide unmatched precision, our systems utilize the Real-Time Transient Model (RTTM), ensuring accurate and timely detection of leaks (sensitivity) under both transient and steady-state conditions. This capability sets us apart and empowers oil producers to maintain operational integrity and environmental compliance seamlessly.

As we continue to refine our technologies, our focus remains on delivering software solutions that enhance safety, streamline operations, and ensure the sustainability of resources and the environment. Join us as we explore what makes our leak detection software a crucial asset for any forward-looking oil producer.

What Sets Our Leak Detection Software Apart?

In an industry where Robsutness and reliability are paramount, our leak detection software stands out by integrating the latest in computational pipeline monitoring (CPM) with the Real-Time Transient Model (RTTM). This combination not only enhances the ability to detect leaks both during transient and steady-state conditions but also ensures that our technology is among the most reliable in the market. The design of our software focuses on three main areas: Reliability, usability, and integration capability.

First, the reliability of our software is unparalleled. Thanks to RTTM, it can quickly differentiate between normal operational changes and potential leaks, significantly minimizing false positives and negatives. This high level of reliability is crucial for maintaining the integrity and efficiency of pipeline operations, ensuring that resources are not wasted on false alarms, while real threats are promptly addressed.

Secondly, usability is also a key feature of our software; it’s designed to be user-friendly, allowing operators to easily monitor and control the system without needing extensive training. Lastly, our software is built to seamlessly integrate with existing infrastructural systems. This integration capability means that oil and gas companies do not need to overhaul their current systems to adopt our technology, making it a cost-effective and convenient solution.

Real-Time Leak Detection: Why Sensitivity and Accuracy Matter

In the context of oil and gas operations, the sensitivity and accuracy of leak detection are not just about preserving resources but are crucial for safety and environmental protection. Our software’s real-time processing power allows it to detect and pinpoint the location of leaks almost immediately as anomalies are identified. This fast response capability is vital in preventing minor leaks from escalating into major disasters that could lead to significant environmental damage and potential harm to human life.

The importance of accurate and speedy leak detection extends beyond emergency responses. It plays a critical role in routine operations, helping maintain system integrity and operational continuity. Fast and accurate leak detection means that operations can be safely continued with minimal downtime, ensuring that productivity levels remain high.

Moreover, this capability helps in maintaining compliance with increasingly stringent environmental regulations, as potential leaks are dealt with swiftly before they can cause significant damage. Thus, by using our leak detection software, oil and gas producers can not only safeguard their assets but also contribute positively toward environmental conservation efforts.

Tailored Solutions for Diverse Oil and Gas Operations

Recognizing the varied needs across different segments of the oil and gas industry, we’ve developed a suite of solutions that cater to the unique challenges faced by our clients. Our offerings aren’t one-size-fits-all; instead, we tailor them to fit the specific requirements of oil producers, gas processing plants, and pipeline transportation companies. For instance, our emulsion pipeline monitoring software is specifically designed for systems where emulsions or mixed fluids are common, ensuring precision in environments where detection can be particularly challenging.

Additionally, our solutions for saltwater injection well monitoring are crucial for operations where water injection is a part of the recovery process. This specific software helps monitor the integrity of pipelines used in water flood operations, which are vital for maintaining pressure in the reservoirs. By ensuring these systems are leak-free, we play an essential role in both environmental protection and resource management, making sure that our clients can operate safely and sustainably.

Looking Ahead: How We’re Shaping the Future of Leak Detection

The evolution of our RTTM-based systems continues as we integrate more advanced AI and machine learning algorithms, which further enhance their detection capabilities. Such innovations are becoming increasingly important as the pipelines we monitor grow in age and as regulatory demands for environmental protection intensify.

Interested in learning more about how our innovations in leak detection software can safeguard your operations? Contact us at Vanmok, and let’s discuss how we can bring this advanced protection to your business!