Leaks in pipelines can cause serious issues, from environmental damage to costly repairs. This is why effective leak detection is crucial for pipeline safety. One powerful tool for this purpose is the Real-Time Transient Model (RTTM). RTTM offers a way to spot leaks as they happen, giving us the chance to act quickly. But what is RTTM exactly, and why is it so important?

RTTM stands for Real-Time Transient Model. It helps monitor changes in flow, pressure, and temperature within pipelines. By doing this, RTTM can detect even the smallest leaks during both steady-state and transient conditions. This model is crucial because it provides real-time data, allowing us to react before small issues become big problems.

Using RTTM in leak detection systems makes pipelines safer and more efficient. It reduces downtime and saves money on repairs. This makes RTTM an essential part of any modern pipeline monitoring strategy. Whether you manage natural gas, oil, or emulsion pipelines, understanding and implementing RTTM can make a big difference in maintaining safety and efficiency.

What is the Real-Time Transient Model (RTTM) and Why It’s Important

The Real-Time Transient Model (RTTM) is a cutting-edge technology used for pipeline leak detection. RTTM helps to monitor pipeline operations under both steady-state and transient conditions. This model works by continuously collecting data on flow, pressure, and temperature within the pipeline. By analyzing this data in real-time, RTTM can quickly identify any anomalies that may indicate a leak. This rapid detection is crucial in minimizing damage and preventing environmental hazards.

RTTM is essential because it ensures the safety and integrity of pipelines. Leaks can cause significant environmental damage, pose health risks, and result in costly repairs. Immediate detection through RTTM allows for quick response, stopping leaks before they become major problems. This technology benefits various industries, including oil and gas producers, processing plants, and transportation companies. By using RTTM, operators can maintain safe and efficient pipeline operations.

Key Features of RTTM in Leak Detection Systems

RTTM is equipped with several key features that make it effective for leak detection. One of its most important features is real-time data analysis. RTTM continuously monitors the pipeline, providing instant feedback on any irregularities. This helps to detect leaks quickly and accurately, ensuring that issues are addressed before they escalate. The real-time nature of RTTM ensures that operators are always aware of the current state of the pipeline.

Another key feature of RTTM is its ability to handle both steady-state and transient conditions. Pipelines often experience changes in flow, pressure, and temperature. RTTM can analyze these changes and distinguish between normal variations and potential leaks. This adaptability makes RTTM a reliable solution for various pipeline conditions. Additionally, RTTM integrates with existing systems, allowing for seamless implementation and minimal disruption to operations.

RTTM also offers remote monitoring capabilities, making it easier for operators to manage pipelines across different locations. This feature is particularly useful for large-scale operations, as it allows for centralized monitoring and quicker responses to potential issues. The versatility and reliability of RTTM make it an indispensable tool for effective leak detection.

Benefits of Using RTTM for Pipeline Leak Detection

Using the Real-Time Transient Model (RTTM) offers multiple benefits for pipeline leak detection. One major advantage is increased accuracy. RTTM continuously monitors a range of variables like flow, pressure, and temperature, allowing it to detect even minor leaks. This precise detection can prevent small issues from becoming significant problems, saving time and money on repairs and cleanup.

Another key benefit is enhanced safety. By detecting leaks early, RTTM helps operators respond faster, reducing the risk of accidents and environmental harm. This quick action is essential for the safety of workers and nearby communities. Plus, early detection means fewer disruptions in pipeline operations, ensuring a smoother, more efficient process.

RTTM also leads to cost savings. The early detection of leaks minimizes damage and costly repairs. Additionally, this real-time monitoring helps to reduce unplanned downtime, making operations more efficient. The financial savings from using RTTM can be substantial over time, making it a smart investment for pipeline management.

How to Implement RTTM in Your Pipeline Monitoring Strategy

Implementing the Real-Time Transient Model (RTTM) into your pipeline monitoring strategy involves several steps. First, assess your current monitoring systems to see how they can integrate with RTTM technology. Many existing systems can be upgraded to include RTTM, making the transition smoother. It’s essential to ensure that all necessary sensors and data collection tools are in place.

Next, train your team. Proper training ensures that everyone understands how to operate and interpret data from the RTTM-based system. This may involve formal training sessions or hands-on workshops. Providing comprehensive training reduces errors and enhances the efficiency of your monitoring strategy.

Finally, monitor and maintain your system regularly. Like all technology, RTTM-based systems need periodic checks and updates. Regular maintenance ensures that the system continues to operate effectively and identifies potential issues before they become serious. By keeping your RTTM system in good working order, you can maximize its benefits and ensure long-term success.

Conclusion

In 2024, effective pipeline leak detection is more critical than ever to ensure safety, efficiency, and environmental protection. The Real-Time Transient Model (RTTM) stands out as a valuable tool in achieving these goals. By offering precise leak detection, real-time monitoring, and integration with existing systems, RTTM provides a comprehensive solution for pipeline management.

Using RTTM has multiple benefits, including increased accuracy, enhanced safety, and significant cost savings. Implementing RTTM into your pipeline strategy involves assessing current systems, training your team, and regular maintenance. These steps ensure that you can fully leverage the advantages of RTTM technology.

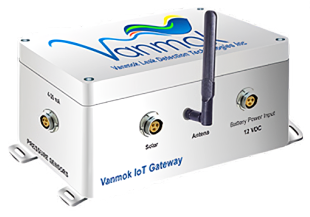

If you’re ready to take your pipeline leak detection to the next level, visit Vanmok to learn how our advanced RTTM-based solutions can meet your needs. We are here to help ensure your pipelines run safely and efficiently.