The oil and gas industry faces numerous challenges in maintaining the integrity of their pipelines. Among the most critical issues is leak detection, especially for natural gas and emulsion pipelines in upstream operations. Leaks can lead to severe environmental damage, safety hazards, and significant financial losses. Therefore, having an effective and reliable leak detection system is crucial.

Real-time leak detection is a game-changer in this context. Traditional leak detection methods often detect problems too late, causing irreversible damage. In contrast, real-time systems continuously monitor pipeline conditions, allowing operators to identify and address leaks as soon as they occur. This proactive approach helps to minimize potential risks and ensures the safe and efficient operation of pipelines.

At Vanmok, we offer cutting-edge leak detection solutions that specifically address the challenges faced by oil and gas producers. Our technology incorporates advanced Computational Pipeline Monitoring (CPM) systems. These tools provide accurate and timely leak detection, even in transient and steady-state conditions. This means less downtime, reduced environmental disruption, and enhanced safety for pipeline operations.

Why Real-Time Leak Detection is Crucial for Natural Gas and Emulsion Pipelines

Real-time leak detection is vital for maintaining the safety and efficiency of natural gas and emulsion pipelines. These pipelines often carry hazardous materials that can cause severe environmental damage and health risks if they leak. Immediate detection allows quick response and minimizes the impact, making real-time monitoring a crucial part of pipeline management.

Leaks in natural gas pipelines can result in gases accumulating in confined areas, posing risks of explosions and fires. Early detection helps prevent such incidents by allowing operators to act swiftly. Similarly, emulsion pipelines, which transport mixtures of oil and water, require constant monitoring to avoid water contamination and oil spills. Quick identification of leaks helps avoid significant environmental and operational disruptions.

Moreover, real-time leak detection is not just about safety; it also ensures operational efficiency. Continuous monitoring reduces unplanned downtime, which can be costly. Identifying and addressing issues before they escalate helps maintain the integrity of the pipeline, reduces maintenance costs, and extends the pipeline’s lifespan. Investing in real-time leak detection makes good economic sense for pipeline operators.

Common Challenges in Detecting Leaks in Natural Gas and Emulsion Pipelines

Pipeline Corrosion and Material Fatigue

Corrosion and material fatigue are significant challenges in pipeline management. Over time, pipelines can corrode due to chemical reactions with the transported materials or external environmental factors. Corrosion weakens the pipeline, increasing the risk of leaks. Material fatigue, caused by repeated stress and pressure changes, also contributes to the deterioration of pipelines. Addressing these issues requires robust materials and coatings, as well as regular inspections and maintenance.

Pressure Variations and Temperature Fluctuations

Pressure and temperature variations pose another set of challenges for leak detection. Natural gas and emulsion pipelines often operate under high pressure and varying temperatures. These conditions can cause expansion and contraction in the pipeline, creating weak points that are susceptible to leaks. Advanced leak detection systems need to account for these fluctuations to maintain accuracy. Variations can affect sensor readings, so compensating for these changes is essential for reliable monitoring.

Regulatory and Safety Compliance

Compliance with safety standards and regulations is crucial for pipeline operations. Regulatory bodies have strict requirements for leak detection and monitoring to ensure public and environmental safety. Meeting these standards can be challenging, as they often require advanced technology and regular reporting. Ensuring that the pipeline meets all compliance requirements involves constant vigilance and investment in state-of-the-art leak detection systems. Failure to comply can lead to penalties, legal issues, and damage to a company’s reputation.

By understanding and addressing these challenges, operators can enhance their leak detection capabilities, ensuring safer and more efficient pipeline operations.

Technologies Used in Real-Time Leak Detection

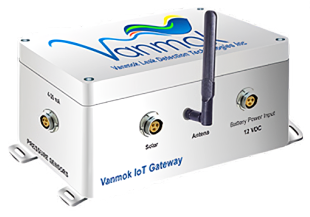

Sensor Deployment and Remote Monitoring

Using sensors for leak detection allows for continuous monitoring and immediate alerts when issues arise. These sensors are strategically placed along the pipeline to collect data on pressure, temperature, and flow rates. Remote monitoring systems analyse this data and provide real-time feedback. This approach enables operators to identify leaks quickly and take immediate action to mitigate any damage. The integration of sensor technology with remote monitoring ensures a comprehensive and proactive leak detection solution.

Computational Pipeline Monitoring (CPM) Systems

Computational Pipeline Monitoring (CPM) systems are essential tools for real-time leak detection. CPM systems use advanced algorithms to compare real-time data with expected pipeline conditions. By continuously analysing this data, CPM systems can detect discrepancies that may indicate a leak. These systems are highly accurate and can identify leaks early, even under transient conditions. CPM systems significantly enhance the overall safety and reliability of pipeline operations.

Advantages of Implementing Vanmok’s Leak Detection Solutions

Enhanced Pipeline Safety and Environmental Protection

Integrating Vanmok’s leak detection solutions significantly enhances pipeline safety. Our advanced technologies provide real-time alerts, enabling quick response to potential leaks. This proactive approach helps to prevent accidents, ensuring the safety of personnel and the surrounding environment. Additionally, early leak detection minimizes the risk of environmental contamination, protecting ecosystems and communities.

Reduced Operational Downtime and Cost Savings

Vanmok’s leak detection solutions also contribute to reduced operational downtime. By identifying leaks early, operators can address issues before they escalate into more significant problems. This results in fewer interruptions and less unplanned maintenance, leading to significant cost savings. Investing in advanced leak detection technology ensures the continuous and efficient operation of pipelines, ultimately benefiting the bottom line.

Tailored Solutions for Various Pipeline Types

Our leak detection solutions are designed to meet the specific needs of different pipeline types. Whether it’s natural gas, emulsion, or produced water pipelines, Vanmok offers tailored solutions that ensure optimal performance. Our technologies are adaptable to various pipeline configurations and operating conditions, providing reliable leak detection across the board. This custom approach ensures that all types of pipelines are well-protected against leaks.

Conclusion

Real-time leak detection is essential for maintaining the safety, efficiency, and reliability of natural gas and emulsion pipelines. The challenges of detecting leaks, such as corrosion, pressure variations, and regulatory compliance, underscore the need for advanced technologies. Vanmok’s state-of-the-art solutions, including sensor deployment, and CPM systems, provide robust and reliable leak detection.

By implementing these technologies, operators can enhance safety, protect the environment, and achieve significant cost savings. Vanmok’s tailored solutions ensure that all pipeline types are adequately protected, contributing to the overall success of pipeline operations.

If you are ready to improve your pipeline safety and efficiency with advanced leak detection technologies, visit Vanmok. Our cutting-edge technologies are designed to meet the unique needs of your operations and ensure the highest levels of safety and reliability.

Visit Vanmok today to learn more about how our solutions can benefit your pipeline operations.