In today’s fast-paced oil and gas industry, maintaining pipeline integrity is not just a safety measure; it’s a crucial part of our operations that directly impacts our efficiency and the environment. We’ve embraced Real-Time Transient Model (RTTM) technology as a core component of our pipeline monitoring systems. This innovative approach has significantly advanced how we detect and address leaks in pipelines, reinforcing our commitment to safety and environmental stewardship.

RTTM technology allows us to monitor pipelines in real time, detecting variations that may indicate leaks during both transient and steady-state conditions. This capability is vital for preemptive detection and immediate response, crucial for maintaining the smooth operation of extensive pipeline networks we manage for our diverse clientele, including oil and gas producers and transportation companies.

By integrating RTTM into our monitoring systems, we ensure higher accuracy and faster responses, minimizing potential environmental impact and operational disruptions. This introduction to RTTM’s role in our operations sets the stage for a detailed exploration of its mechanisms, applications, and future potential in transforming pipeline safety standards. With us, stay ahead in ensuring robust pipeline security and efficiency.

What Is Real-Time Transient Model (RTTM) Technology?

Real-Time Transient Model (RTTM) technology is a sophisticated approach used in our pipeline monitoring systems to detect leaks accurately and promptly. This technology works by analyzing changes in conditions like flow rate, pressure, and temperature within the pipeline system.

RTTM is designed to detect both minor and significant changes, making it exceptionally reliable during various operational states—whether the pipeline is in a steady state or undergoing transient conditions such as startups, shutdowns, or operational mode changes.

The essence of RTTM lies in its ability to use real-time data to provide a dynamic model of the pipeline, updating continuously as new data comes in. This model helps predict and detect discrepancies that could indicate a leak, long before traditional methods might notice an issue. The immediate response enabled by RTTM not only minimizes the environmental risks but also reduces the potential for costly repairs and downtime.

How RTTM Technology Enhances Pipeline Safety

Implementing RTTM technology within our leak detection systems significantly enhances pipeline safety in several key ways. Firstly, the real-time data analysis allows us to notice irregularities almost immediately. Quick detection is crucial for addressing leaks early, preventing the escalation of potential hazards or environmental damage. This swift response capability is vital for maintaining safe operations and protecting surrounding ecosystems, which is a significant advantage for us and our clients.

RTTM technology’s precise detection minimizes false alarms—a common issue in less advanced systems that can lead to unnecessary operational interruptions and increased maintenance costs. By ensuring that only true threats are flagged, our teams can focus their efforts on actual problems, enhancing overall efficiency and safety.

Additionally, this accuracy plays a critical role in compliance with environmental regulations, helping us and our clients maintain a responsible operational profile that upholds safety standards and protects against legal and social liabilities.

Exploring the Various Applications of Our Leak Detection Systems

Our innovative Real-Time Transient Model (RTTM) technology is not just about enhancing safety; it’s also about versatility across various applications. We proudly serve an array of clients, including oil and gas producers, processing plants, and transportation companies. For each client, the application of our technology is fine-tuned to meet specific industry needs and challenges.

For instance, in oil pipeline operations, our systems play a crucial role in monitoring for leaks that could otherwise lead to significant environmental and economic damage. Similarly, in produced water pipelines, our technology ensures the safe disposal or re-injection of water produced during oil extraction, preventing environmental hazards.

The versatility extends to emulsion pipelines and saltwater injection wells, where monitoring is critical to maintaining operational integrity and environmental compliance. This wide-ranging application shows our commitment to providing comprehensive solutions tailored to each sector’s needs.

The Future of Pipeline Monitoring with Our Real-Time Solutions

Looking ahead, the future of pipeline monitoring is promising, thanks to ongoing advancements in Real-Time Transient Model technology. We’re dedicated to continuous improvement and innovation, ensuring that our systems meet current industry standards and set new benchmarks for safety and efficiency.

Our forward-thinking approach involves integrating more advanced sensory technologies, enhancing computational models, and incorporating artificial intelligence to predict and prevent leaks before they happen. As pipelines become “smarter,” our real-time monitoring systems are set to become more autonomous, providing critical data that will drive decisions in pipeline management and maintenance without human intervention.

Ensuring Energy Security: Our Technology’s Role in Pipeline Safety

Embracing our RTTM-based leak detection systems means investing in a future where pipeline operations are safer, more efficient, and less disruptive to the environment. As we continue to innovate and expand our technology, the goal is clear: to provide industry-leading solutions that detect, prevent, and manage pipeline leaks with unprecedented precision and reliability.

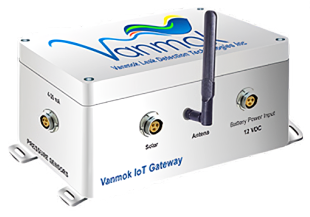

Interested in learning more about how our leak detection system pipeline technology can protect your operations? Get in touch with our team at Vanmok and discover how we can help you stay ahead in pipeline safety and efficiency.