The system calculates and displays any discrepancy between actual values and predicted values to verify that processes are moving as expected. The process allows users to increase the efficiency of their operations by quickly identifying the source of leaks and implementing remedial efforts. This way, organizations are able to prevent costly downtime, ensure streamlined processes, and minimize environmental disruption.

The Real-Time Transient Model (RTTM) is applied to pipeline leak detection by creating a simulation environment that mimics the behavior of the pipeline using computational algorithms. Field instrumentation feeds data into the model about pressure, mass flow, density, and temperature, among several other variables.

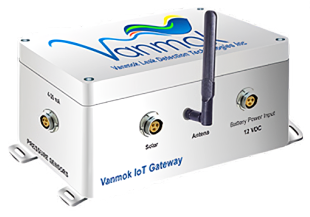

Vanmok LD™ is based on Extended Real-Time Transient Model (E-RTTM).