With increasing environmental concerns, regulatory and CSA Z662-23 standard requirements, leak detection in all pipelines has become a top priority for the energy industry in recent years. Real time leak detection on the upstream pipeline gathering networks carrying emulsions from oil wells to separation facilities is very challenging due to the presence of multiple fluid phases in the pipelines. Due to the unavailability of minimum required instrumentation, SCADA/telemetry on the gathering pipeline network and operational complexity, conventional leak detection methods such as volume balance or real time transient modeling are not possible to implement on these pipelines. In addition, the cost-effectiveness of these technologies doesn’t make it economically feasible to implement them. In this paper, an approach to monitor the emulsion pipeline networks for leak detection using a pressure-based machine learning algorithm is presented. The machine learning-based algorithm uses the pressure data from the beginning and end points of the network to form a closed system that supports creating a decision on whether there is a leak within the pipeline or not.

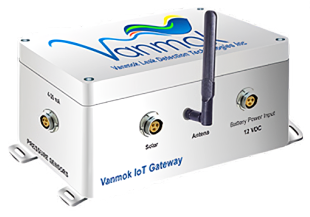

This paper will demonstrate that with pressure transmitters at the beginning and end points of the pipeline network carrying emulsions, it is feasible to monitor the state of the emulsion pipelines and measure its effectiveness using leak sensitivity, algorithm reliability and robustness during abnormal and degraded operating conditions as the key metrics. The paper will delve into the intricacies of high-frequency data transmission IoT devices to a private cloud system, which plays a pivotal role in continuously monitoring pipeline networks for leaks. The application of this algorithm will be shown for three different pipeline networks with each pipeline containing fluids that have different phase compositions. The paper describes the performance of this algorithm for incidents ranging from small leaks equivalent to a quarter inch leak hole and a full-bore pipeline rupture, which equates to a loss of volume approximately equal to 5-50% of the nominal pipeline flow rate.