If the Persian Gulf War oil spill and Deepwater Horizon oil spill have taught us one thing, there’s no such thing as excessive measures for spill prevention and safety measures in the oil and gas industry. Particularly, safety mechanisms to prevent pipeline leaks are necessary to protect the environment and aquatic life from catastrophic damage as well as to avoid costly fines and penalties.

Due to heavy scrutiny and stringent regulations, oil and gas companies use advanced leak detection systems like Computation Pipeline Monitoring (CPM) to prevent oil spills. However, not every CPM is made the same. Many CPMs cannot accurately differentiate between a leak and a column separation, which can lead to an array of problems in addressing and fixing these problems. Let’s find out more!

Pipeline leaks

Pipeline leaks occur due to metal loss due to corrosion, manufacturing or construction defects, and cracks. It can cause the uncontrolled release of petroleum into the ocean or coastal waters that can be detrimental to the marine ecosystem and the environment. A leak can be a small crack, pin hole, or opening that allows the liquid inside the pipe to seep outside and cause pollution. It poses a significant threat to public health and the environment.

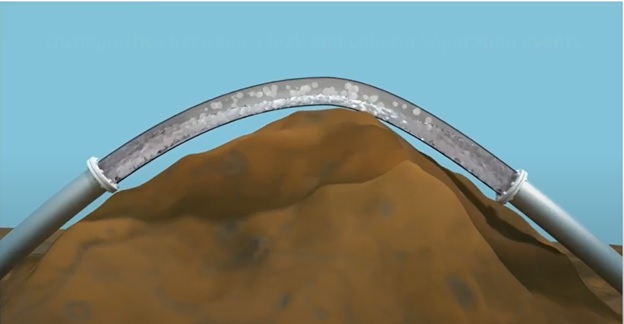

Column separation

Column separation refers to the “phase change of crude oil or any hydrocarbon from liquid to vapour” in pipelines. Analyzing this risk is necessary to ensure the operational safety of the oil or liquid hydrocarbon (NGL, LPG, Ethane and other C2+) transport pipeline. It can impact a pipe’s integrity and operations, especially when there’s no system in place to manage its occurrence.

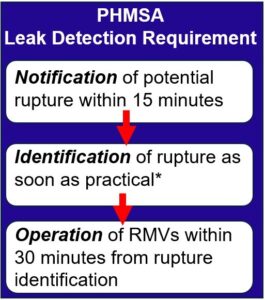

Now, pipeline operators can monitor by a Computation Pipeline Monitoring system to identify column separation, leaks and take action to prevent further damage.

How Can Vanmok Help?

Vanmok Leak Detection Technologies offers research-driven and innovation-empowered pipeline leak detection solutions to our clients. Equipped with Artificial Intelligence and Data Analytics, we offer pipeline leak detection technology that can accurately diagnose leaks and column separation. Our Vanmok LD Studio comes with a built-in module for Column Separation or Slack line prediction.

Our Columnfinder® can be a valuable tool for controllers to address column separation problems. It can efficiently recognize, interpret, implement, and monitor the process. It has the capability to distinguish between a column separation and a leak. Our CPM systems are based on Real-Time Transient Model (RTTM). Call +1(780) 989 1286 or send an email at info@vanmok.com to get in touch. For more details, visit our website today!