Vanmok offers leak detection solutions that are highly cost competitive in the current market. Our midstream customers, particularly those with short or Type A gathering pipelines, seek results with the lowest possible investment and maintenance costs. This case study compares the total installed cost of Vanmok Cloud solution with a CPM-based approach in short midstream applications involving refined and partially-refined fluids.

Problem: With increasing public awareness of pipeline operations and leak containment, regulatory requirements are also on the rise. There is a need for a reliable and highly responsive system that minimizes false alarms and effectively addresses environmental damage when leaks occur. While many midstream customers already employ Computational Pipeline Modeling (CPM) for their long-haul linear assets, implementing and calibrating these systems for short pipelines can be costly.

We have conducted a total cost of ownership comparison between a CPM-based technology and Vanmok Cloud solution.

Technical Comparisons: CPM solutions typically rely on temperature and pressure compensated flow metering. However, the total installed cost of these systems becomes economically infeasible for short pipelines due to the expenses associated with flow meter instrumentation and the need for numerous pipe diameters to ensure consistent flow profiles. Given the large number of short pipelines used by our midstream customers, a CPM-based solution quickly becomes uneconomical.

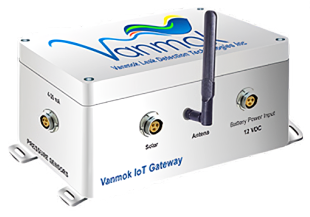

On the other hand, Vanmok Cloud solution employs only pressure transmitters to detect leaks in short pipelines, making it exponentially cheaper to install compared to a CPM-based approach. We achieve this through our proprietary analysis of upstream and downstream pressures using advanced fluid dynamic analysis and machine learning data analytics, developed over years of research.

In this analysis, we have not factored in the cost avoidance resulting from CPM-based false alarms due to poorly calibrated and tuned systems. These related costs include premature pipeline shutdowns, investigations by operations personnel, and, in the worst case, the failure to detect a true leak. The Vanmok solution is autonomous and continually self-tunes its algorithm using machine learning, substantially reducing the number of false alarms while improving system reliability.

Setup Cost Comparison: Vanmok’s pressure monitoring solution relies solely on upstream and downstream pressure transmitters, eliminating installation and maintenance costs associated with flowmeters. Additionally, flowmeters become unreliable in cases where the flow profile is erratic and falls beyond the tuning parameters of the system. In summary, flow meters not only cost more as individual units, but they also incur higher commissioning, tuning, and maintenance expenses.

The table below presents a cost comparison between the two technologies.

| Cost Item | Units | CPM-based | Vanmok |

| Data Acquisition System (SCADA) | each | 1x | 1/3x |

| Initial system tuning | $/system | 1x | 1/10x |

| Total cost/pipeline | 1x | 1/6x | |

| Pipeline Company expenses | |||

| Engineering and design | 1x | 1/4x | |

| Pressure transmitters | each | $2,500 | $2,500 |

| Flow meters | each | $30,000 | Not required |

| Flow meter piping mod’s | $/site | $20,000 | Not required |

| Flow meter installation | $/site | $10,000 | Not required |

| Total cost of ownership | $ in year 1 | 1x | 1/10x |

| Total expenses to implement per site | $ in year 1 | $64,500 | $2,500 |

| Total savings in the first year | $/site | – | $130,000 |

Operation and Maintenance Costs: CPM-based systems that employ flowmeters incur higher annual repair and maintenance costs. These costs include recalibration, retuning, and long-term energy losses due to additional piping configurations.

| Cost Item | Units | CPM-based | Vanmok |

| Annual monitoring fees | $/year | 1x | 1/5x |

| Flow meter calibration | $/year | $2,000 | Not required |

| Total annual cost of ownership | $/year | 1x | 1/5x |

Summary: Vanmok estimates that its Cloud-based leak detection technology costs 5 times less than a CPM-based system on a per-site basis per year and saves approximately $130,000 per site in the first year. In addition to the significant cost savings, the Vanmok solution offers the following advantages to our customers:

- Meets API-1130 performance metrics.

- PHMSA compliant for short or Type A pipelines.

- Eliminates the need for flowmeters.

- Installation costs are 5 times lower than CPM.

- Increased operator confidence.

- Fewer false alarms.