The challenge is too many false alarms at the expense of capital spending for flow meters and piping modification to accommodate the incumbent leak detection system. Due to the cyclic and continuously transient nature of the pipeline, it is very challenging for the leak detection systems to have fewer false positive alarms while maintaining the capability to detect small leaks. If there are too many false alarm in a month, operators cannot attend all those alarms to verify them. Lot of those alarms will go unnoticed. If there is a real leak, it would be missed to respond promptly and mitigate the environmental damage. A leak incident would cost company to clean up in millions of dollars and also face regulatory scrutiny and fines.

If you do, we would like to talk to you about a solution that Vanmok has developed. If you think multiphase leak detection in your gathering network is a pain for your company? And If you are looking for a solution, book a demo now to see how it works to detect leaks cost effectively!

If you do, we would like to talk to you about a solution that Vanmok has developed. Vanmok LD Cloud is a cost effective, real-time and autonomous solution for leak detection in Emulsion pipeline networks. The field proven technology can detect the leaks from pinholes to large ruptures in less than few minutes by using proprietary algorithms for leak detection.

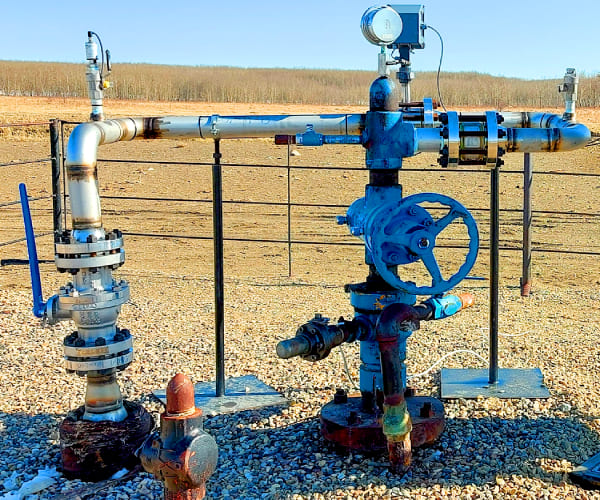

Customer: “How do we find leaks in pipelines disposing salt water from FWKO to wells under vacuum without using expensive flow meters and piping modifications? We don’t have SCADA or telemetry.”

Vanmok LD Cloud is the answer!

Relies on pressure transmitter data only.

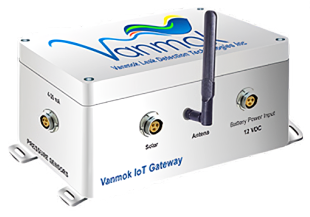

Dedicated Vanmok loT gateway scans data at 50 milli seconds and communicates to Cloud through cellular network (LTE-M or LTE-4G)

Built-in Vanmok A.I analyses all alarms and validates before alerting the operators.

Low power Vamok Gateways are supplied with integrated solar system to work offgrid.

Notifies and identifies leaks from 5% or greater within 15 minutes using only pressure transmitters.

Eliminates the need to modify existing piping to install flowmeters, saving expenses on both piping modifications and flowmeters.