Vanmok offers leak detection solutions that are highly cost competitive in the market. Our upstream customers prioritize low investment and maintenance costs for their production-related gathering and water disposal systems. This case study compares the total installed cost of Vanmok Cloud based leak detection solution with competing technologies in emulsion and salt water applications.

Problem: As public awareness of pipeline operations and leak containment increases, regulatory requirements also become more stringent. Our upstream customers require cost-effective solutions that not only meet regulatory standards but also minimize nuisance alarms, operator burden, delayed diagnosis, and potential cleanup costs and regulatory implications resulting from system malfunctions.

To quantify the cost advantages of Vanmok Cloud solution, we have prepared this cost comparison against competing technologies available in the market.

Competitive Alternatives: In this space, there are two leading technologies available to our customers:

- Material balance involving flowmeters (Competitor)

- Pressure-only monitoring (Vanmok)

Both solutions require pressure transmitters at each end of the pipeline segment. However, the competitive solution additionally requires flowmeters at each end to perform the material balance calculation. Flowmeters pose several challenges, including the need for more pipe modifications, longer production outages, frequent calibration, and higher annual maintenance costs to maintain measurement accuracy. Moreover, flowmeters perform poorly, or not at all, in emulsion or mixed-phase applications.

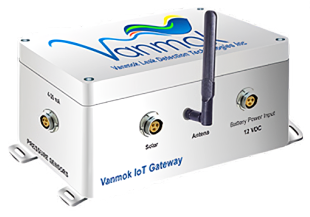

Setup Cost Comparison: Vanmok’s pressure monitoring solution relies solely on upstream and downstream pressure transmitters, eliminating the need for flow meters and associated costs.

The table below compares the costs of various components for the two technologies:

| Component | Units | Competition | Vanmok |

| Pressure Transmitters | each | $900 | $900 |

| Flowmeters (Turbine) | each | $2,500 | Not required |

| Flowmeter piping mod’s | $/site | $5,000 | Not required |

| Flowmeter installation | $/location | $1,000 | Not required |

| Flowmeter calibration | $/year | $600 | Not required |

Operation and Maintenance Costs: In saltwater and emulsion applications, flowmeters incur higher annual repair and maintenance costs. Flowmeters are prone to wax buildup during normal operation, leading to false alarms and costly maintenance and production losses required to clear out the instrumentation.

Summary: We estimate that the total installed cost of Vanmok solution is 10 times lower than that of competing technologies. This includes the cost avoidance of ongoing maintenance for applications using flowmeters. Additionally, Vanmok’s machine learning algorithm continuously learns from alarm conditions, significantly reducing the number of false alarms to 1 or 2 per year within the first year of operation.

Value to Customer:

- Elimination of flowmeters.

- Total installed cost 10 times lower than alternatives.

- Increased operator confidence.

- Reduction of false alarms to 1 per year.

Vanmok system provides:

- Best sensitivity (up to 3% leak rate or 1 m³/hr).

- High reliability (1 alarm per quarter per pipeline).